LIFE SMART replaces fossil coal with end-of-life residues

We avoid the use of fossil resources by using local waste-based, non-recyclable resources, thereby recovering their intrinsic chemical value.

Latest news

Read more newsAbout us

We will be replacing fossil resources in steelmaking with end-of-life, renewable resources.

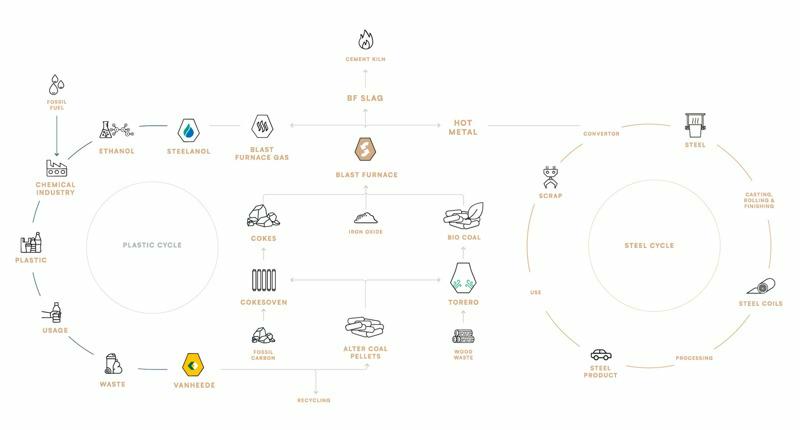

The LIFE SMART project takes an innovative approach on the steelmaking process by replacing fossil resources with renewable, end-of-life non-recyclable resources in the form of AlterCoal® pellets. These pellets are fed to either the coking plant or the torrefaction installation, where they are transformed into cokes or powder coal, which are then used in the process to produce steel. By transforming the pellets to these intermediate products their intrinsic chemical value is recovered, as it serves as a critical component in the steelmaking process. During the project the pellets will be tailored to fit the needs of the steelmaking projects.

The process

Integration of AlterCoal pellets in the steel mill

The steelmaking process uses fossil coal and iron ore as inputs to produce liquid steel. The fossil coal is a critical element in this process as it contains reducing carbon and hydrogen atoms (C & H) that are able to extract the oxygen atoms (O) from the iron ore (FexOy), thereby producing iron (Fe). The fossil coal is used in the form of cokes (hard, porous material) and powdered coal (very fine material).

The LIFE SMART project aims to replace part of the fossil coal feedstock by using an alternative feedstock: end-of-life non-recyclable residues. These residues are introduced in the steelmill in the form of AlterCoal® pellets, a mix of different non-recyclable residues specifically designed during this project.

The AlterCoal® are then transformed into intermediate cokes or powder coal in the coking plant or the torrefaction installation. These intermediates are then fed to the blast furnace, where their carbon and hydrogen atoms are used to reduce the iron ore.

The off-gasses produced during steelmaking may be converted to ethanol, a platform molecule for the chemical industry, in the Steelanol installation. As this platform molecule can be used to make plastics, a closed loop can be achieved as the produced plastic may end up as an end-of-life residue, which can again be processed in an AlterCoal® pellet.

EUROPA

With the support of the European commision

The LIFE SMART project has received funding from the LIFE Programme of the European Union.