Next step towards carbon neutral steel: SMART or SteelMaking with Alternative Reductants

24 February 2022

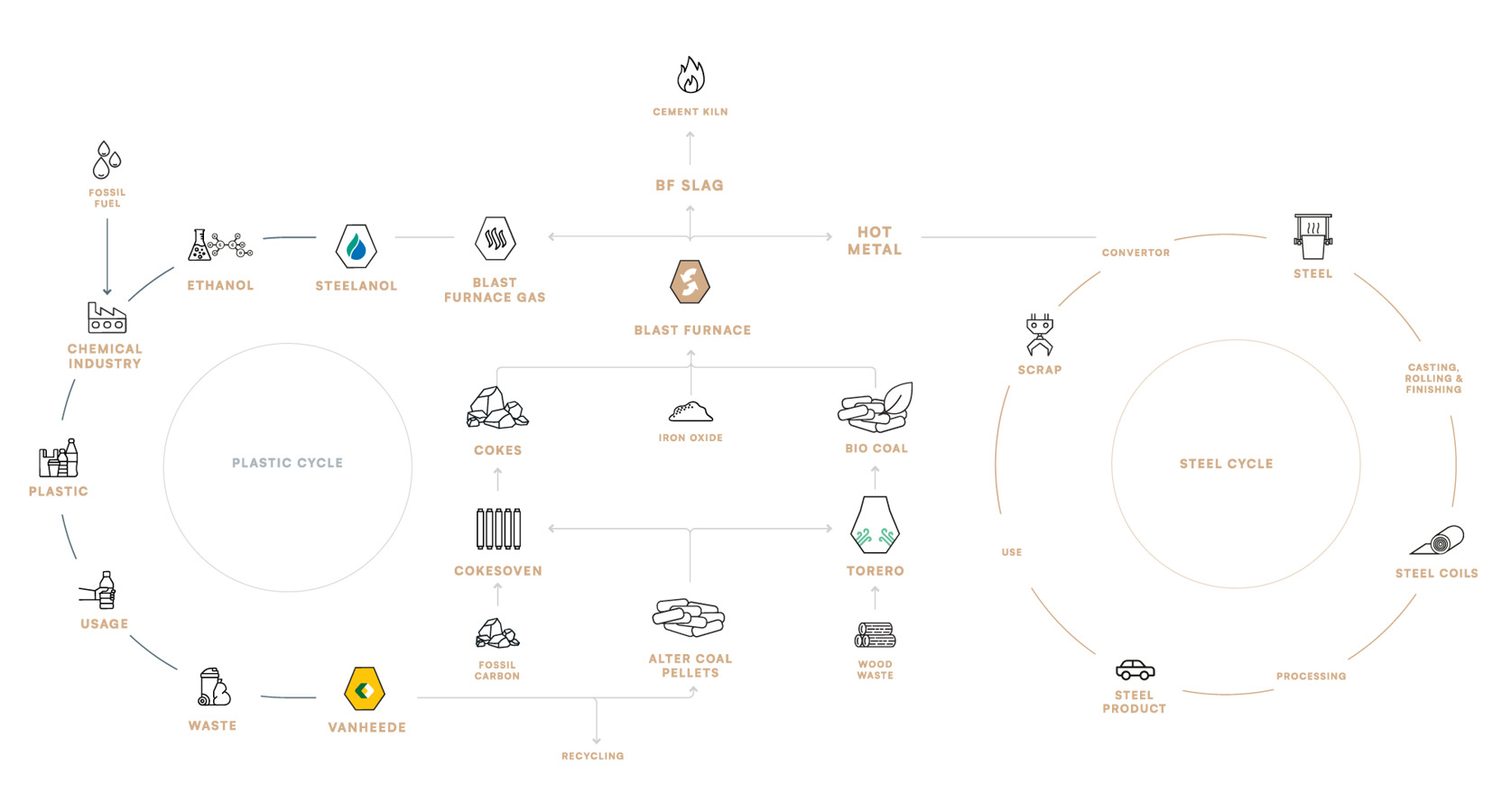

In the steelmaking process, so-called ‘reductants’ are needed to transform iron ore into hot metal. The SMART project allows us to replace fossil carbon-containing reductants such as coal with circular waste-based reductants, hence the project acronym SMART: SteelMaking with Alternative Reductants.

To this end, Vanheede Environment Group, an integrated environmental company located in Belgium, will supply ArcelorMittal with AlterCoal® pellets. These pellets are a mixture of industrial residuals and non-recyclable plastics with a high carbon content. Using dedicated CRM Group and Ghent University expertises in high temperature processes, the SMART project will allow to chemically recover these AlterCoal® pellets into metallurgical coke and into pulverised coal. Both take on the role of reductant and energy source in the blast furnace.

By reducing the use of fossil carbon, we will reduce our CO2 emissions and provide a solution for particularly difficult waste streams, such as non-recyclable plastics. The SMART project is yet another step forward in our ambition to become the sustainable steel plant of the future, the cornerstone of a circular economy.

The SMART project is a collaboration between ArcelorMittal, Vanheede Environment Group, Ghent University and CRM Group. More information can be found at https://www.life-smart.eu/. The project is funded by the LIFE program of the European Union (LIFE19 CCM/BE/001215) for an amount of 3.4 million euro. The LIFE program is the EU’s subsidy instrument for the environment and climate action created in 1992.

About Ghent University

Ghent University (UGent) is a top 100 university in the Shanghai Ranking and one of the largest Belgian universities in the heart of Europe. We are an active partner in national and international educational, scientific and industrial cooperation. Our organisation is dedicated to research and innovation with an annual research budget of over €600 million and more than 5,500 researchers active in a wide range of life, physical and social sciences. UGent TechTransfer and UGent Business Development Centres, such as Metals, and CAPTURE (Centre for Advanced Process Technology for Urban Resource Recovery), support researchers in developing cutting-edge science to bring innovations to the market.

About Vanheede Environment Group

Today, Vanheede offers more than 15,000 customers a sustainable, efficient and economical solution for waste management. The company plays a key role in the realisation of the circular economy by processing every waste flow into new materials or energy, both in its own and external processing sites. Vanheede Environment Group is one of the top 5 companies in the Benelux, Luxembourg and Northern France. The company has over 800 employees spread over 13 sites in Belgium, Luxemburg and France. The entire group of companies processes more than 1,000,000 tonnes of waste annually, 94% of which has a useful destination. As an integrated environmental company, Vanheede Environment Group manages 2000 waste streams with the vision "Towards a circular world, in a sustainable way". Thanks to its high-performance processing sites, it guarantees the production of more than 42 million kWh of green energy. Vanheede Environment Group has a consolidated turnover of 160 million euro.

About CRM group

CRM Group activities are centered on the production, transformation, coating and use of metallic materials. Since 1948, CRM Group offers R&D and technology solutions focusing on the development of innovative processes and products that create value for its industrial partners. CRM Group is based in Belgium (Liège and Ghent) and operates worldwide; it combines skilled and experienced research teams with unparalleled testing facilities covering the whole manufacture chain of metals, from raw materials to advanced steel applications, ranging in size from laboratory scale to pilot and even semi-industrial production lines.

About ArcelorMittal Belgium

ArcelorMittal Belgium, with production sites in Ghent, Liège, Genk and Geel, employs 5,000 people. The total direct and indirect employment is estimated at 30,000 jobs. The company produces high-quality steel for the most diverse applications in the automotive sector and other industrial sectors such as the green energy sector, construction, white goods, packaging, etc.

Contact person ArcelorMittal

Jan Cornelis

jan.cornelis@arcelormittal.com

Tel.: +32 (0)9 347 35 72 / +32 (0)499 599 394

Contact person UGent

Karen Hemelsoet (PhD) - Business Developer Metals

Karen.Hemelsoet@UGent.be

Tel.: +32 (0)9 331 04 91 / +32 (0)484 690 434

www.ugent.be/metals/en/

Contact person CRM

Jean Borlée

jean.borlee@crmgroup.be

Tel.: +32 (0)485 682 887

Contact person Vanheede Environment Group

Nico Kimpe

Nico.kimpe@vanheede.com

M. +32 (0)477 996 425